Hot Products

Our Advantages

-

Customization

We provide a full-chain, one-stop non-standard bearing customization service. Our proprietary factory controls the entire process—from raw materials to final delivery—ensuring traceable quality. We develop tailor-made solutions based on customer drawings or samples, offering modifications such as heightened inner rings, grooved outer rings, and special tolerances to meet unique operational needs.

-

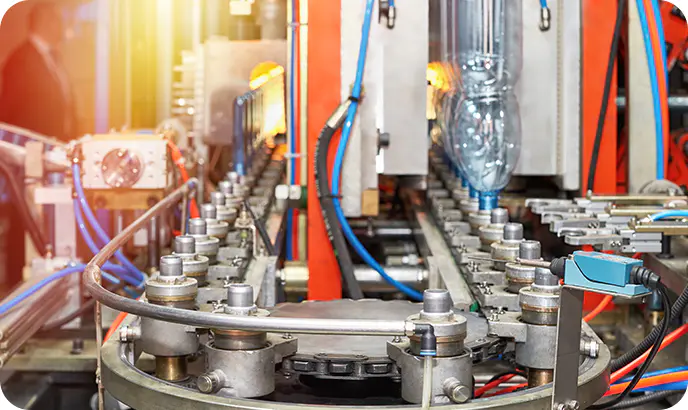

Quality

We implement a full-process quality control system to ensure high precision and consistency. Utilizing specialized measuring and testing equipment, we strictly monitor key tolerances like inner/outer diameter and roundness. Every bearing undergoes standardized factory inspections—including flatness and appearance checks—with synchronized data recording to enable full traceability and prevent defect outflow, guaranteeing stable and reliable product performance.

-

Multiformity

We have established a two-tier product system of "Proprietary Core Models + Alliance Extended Models" to meet bearing application needs across various industries. Our proprietary factory supplies 40 mature mainstream models, ensuring stable availability of standard products. Through collaboration with five partner factories, we offer an additional 230 models covering specialized categories such as non-standard customization, special materials, and high-precision bearings, fully addressing diverse and multi-batch procurement requirements.

-

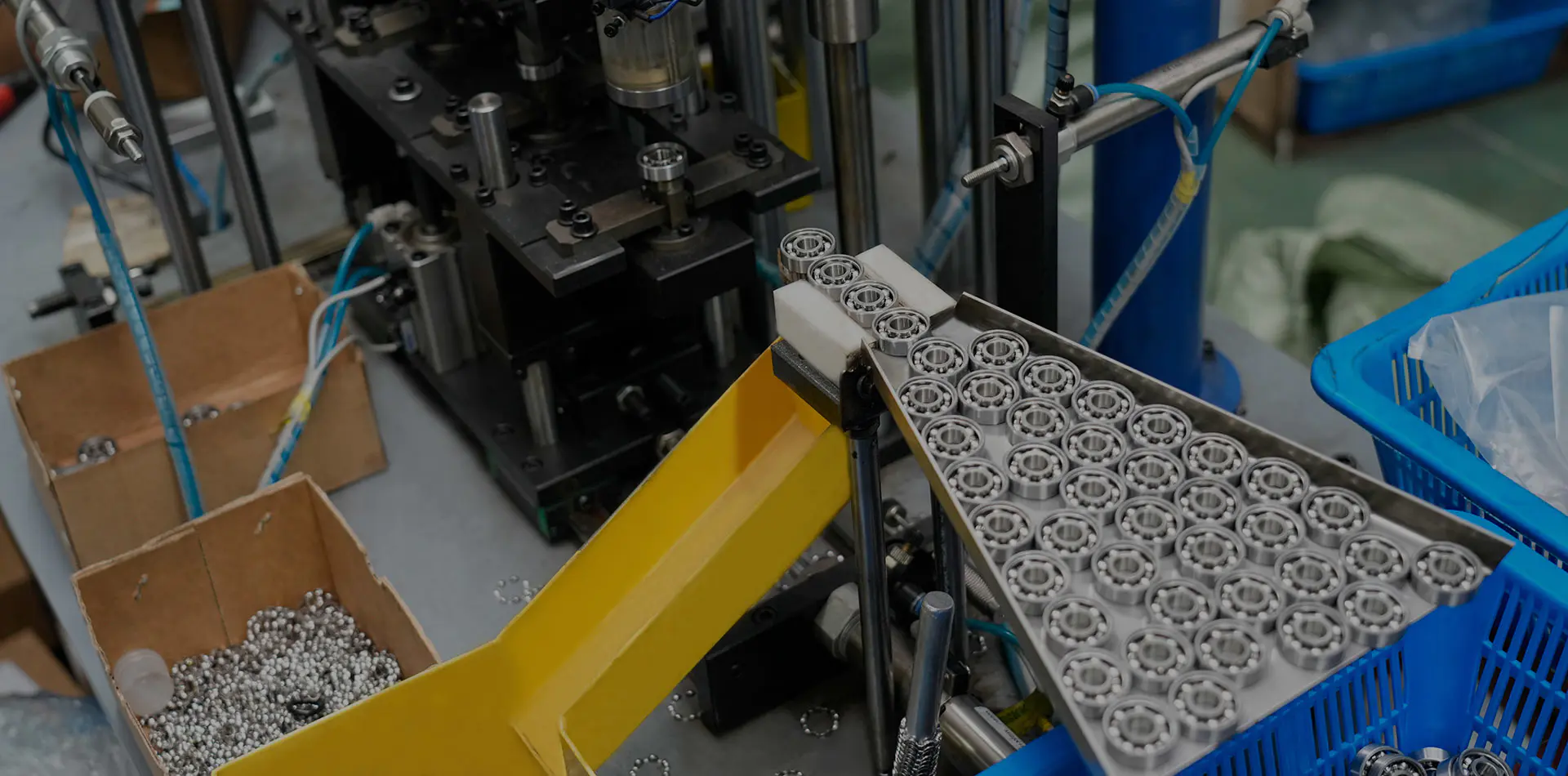

Capacity

We maintain a reliable supply system supported by proprietary production capabilities. Our dedicated factory specializes in mass-producing deep groove ball bearings, with an annual output of 13–15 million sets, enabling secure and timely bulk deliveries. Production capacity is scalable and follows a steady growth trajectory based on market demand, ensuring flexible, long-term supply support for customers.

-

Cost

We leverage a composite supply system combining proprietary and alliance factory capacities to offer cost-effective, diversified products. Our own factory provides direct pricing advantages by eliminating middleman markups, ensuring quality and competitive prices. Through collaboration with 5 specialized alliance factories, we achieve full product coverage and enhanced efficiency, enabling flexible procurement solutions with strong price competitiveness.

-

Customization

-

Quality

-

Multiformity

-

Capacity

-

Cost

English

English